Embroidery

Process – The garment is stitched with your custom design using an industrial embroidery machine.

Pros – Can be used on almost any garment giving you a 3D effect using multiple colours and is long lasting.

Cons – The back of the garment may feel irritable in the beginning until its washed.

Screen Printing

Process – Your custom design is pressed through a screen on to a garment of your choice. It is then passed through an oven to seal the print on to your garment.

Pros – Screen printing is long lasting and gives your custom design a sharp finish as the ink is infused into the fabric. It is also a cheaper option when doing high volumes.

Cons – Each different colour used in your custom design requires a new screen, meaning there is a limit on how many colours can be used. Screen printing does last; however, you cannot iron over the print.

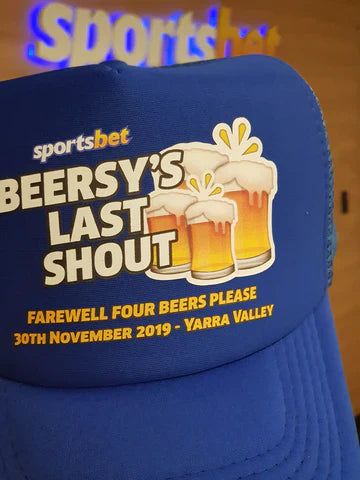

Heat Transfer

Process – Your custom design or logo is printed and then heat pressed onto a garment of your choosing.

Pros – Heat transfer allows you to print multiple colours to create a sharp image that is very price efficient, especially for small quantities. This form of branding can also be done on hard to get to areas on garments and there is no set up cost.

Cons – In order to ensure that the quality of your logo lasts you will need to take care when washing and there is still a possibility that it may come off over time.

The print may peel away if washed in hot water or tumble dried. Wait for 24 hours before you wash T-shirt with newly transferred image. If dye-based ink is use for printing, wait for 48 hours. When washing, make sure the T-shirt is inside out, and do not use aggressive detergent or bleach. Do not tumble dry.Do not directly iron on the image; iron on the inside. Fabrics should be machine washed separately in coolor cold wash setting.

Dye Sublimation

Process – Your custom image or artwork is dyed onto a fabric that is the exact shape and size of your chosen garment. This form of branding allows your design to be embedded into the fabric itself, creating stunning and permanent colours.

Pros – This form of branding creates long lasting designs that can be created with unlimited colours, making your garments fully customised.

Cons – This process can take longer in production and is mainly only done with polyester fabrics and used in the sporting industry.

Direct to garment (DTG)

Process – Ink is printed directly onto a garment, similar to a bubblejet printer. Once printed, the garment passes through an ‘oven’ to set the ink into the fabric.

Pros – You can have endless colours and achieve photo quality print. This is a prefect option for small print runs as there is no set up fee. Price is determined by the size of the print.

Cons – Artwork must be supplied in vector PDF and the best fabric to print on is cotton. We encourage samples to confirm colour and clarity before we go into full production.

Wait for 24 hours before you wash T-shirt with newly Printed image. If dye-based ink is use for printing, wait for 48 hours. When washing, make sure the T-shirt is inside out, and do not use aggressive detergent or bleach. Do not tumble dry. Do not directly iron on the image; iron on the inside. Fabrics should be machine washed separately in coolor cold wash setting. The colours of print may fade away if washed in hot water or tumble dried.